- 非IC关键词

西安尚平电子科技有限公司

- 营业执照:未审核经营模式:其他所在地区:陕西 西安

收藏本公司 人气:37277

企业档案

- 相关证件:

- 会员类型:普通会员

- 地址:长安南路449号

- 传真:029-87878338

- E-mail:xacomponents@163.com

您的当前位置:西安尚平电子科技有限公司 > 元器件产品

产品信息

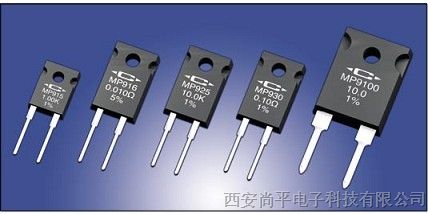

Power Film Resistors TO-126, TO-220 and TO-247 Style

15 Watts at +25°C Case Temperature, derated to zero at +150°C.

Exposed Ceramic Heat Dissipating Mounting Surface.

Resistance Range of 0.020 ohm to 1 K.

Non-Inductive Design.

Use your thermal design experience with power semiconductors in TO-126, TO-220,

and TO-247 style power packages to help you get the most out of this unique family of

power resistors. The thermal design issues are the same where power handling

capability is based on the case temperature which is maintained in your design.

MP915 TO-126 Style Power Package

Up to 30 Watts at +25°C Case Temperature, derated to zero at +150°C.

Exposed Ceramic Heat Dissipating Mounting Surface.

Resistance Range of 0.010 ohm to 100 K.

Non-Inductive Design.

MP916, MP925, and MP930 TO-220 Style Power Package

100 Watts at +25°C Case Temperature, derated to zero at +175°C.

Exposed Ceramic Heat Dissipating Mounting Surface.

Resistance Range of 0.050 ohm to 100 ohm.

Non-Inductive Design.

MP9100 TO-247 Style Power Package

Low Cost Heat Sink Mountable Design featuring

an Exposed Ceramic Heat Dissipating Mounting Surface

The MP900 and MP9000 Series Kool-Pak®

Power

Film Resistors are constructed with Caddock's

Micronox®

resistance film fired onto a flat ceramic

substrate. The terminal attachment and resistance

element geometry are configured to provide

outstanding non-inductive performance. The

ceramic substrate is positioned in the molded

package such that the resistor element and terminal

attachment areas on the substrate are

encapsulated in the molded body with the other side

of the ceramic being exposed flush with the back

mounting surface of the device. This construction is

covered by one or more issued patents, also

patents pending.

For custom resistance values and tolerances contact

applications engineering.

Construction of MP900 and

MP9000 Series:

0.020 Ω 5%

0.025 Ω 5%

0.030 Ω 5%

0.033 Ω 5%

0.040 Ω 5%

0.050 Ω

0.075 Ω

0.10 Ω

0.15 Ω

0.20 Ω

0.25 Ω

0.30 Ω

0.33 Ω

0.40 Ω

0.50 Ω

0.75 Ω

1.00 Ω

1.50 Ω

2.00 Ω

2.50 Ω

3.00 Ω

3.30 Ω

4.00 Ω

5.00 Ω

7.50 Ω

8.00 Ω

10.0 Ω

12.0 Ω

15.0 Ω

20.0 Ω

25.0 Ω

27.0 Ω

30.0 Ω

33.0 Ω

40.0 Ω

47.0 Ω

50.0 Ω

56.0 Ω

75.0 Ω

100 Ω

120 Ω

150 Ω

200 Ω

250 Ω

300 Ω

330 Ω

400 Ω

470 Ω

500 Ω

560 Ω

750 Ω

1.00 K

1.50 K

2.00 K

2.50 K

3.00 K

3.30 K

4.00 K

5.00 K

7.50 K

MP915, MP925, and MP930

Standard Resistance Values:

Tolerance MP915, MP925, and MP930 ±1% Standard - except

as noted. (5% and 20% are available for most resistance values).

0.050 Ω

0.075 Ω

0.10 Ω

0.15 Ω

0.20 Ω

0.25 Ω

0.30 Ω

0.33 Ω

0.40 Ω

0.50 Ω

0.75 Ω

1.00 Ω

1.50 Ω

2.00 Ω

2.50 Ω

3.00 Ω

3.30 Ω

4.00 Ω

5.00 Ω

7.50 Ω

8.00 Ω

10.0 Ω

12.0 Ω

15.0 Ω

MP9100 Standard Resistance Values:

Tolerance MP9100 ±1% Standard.

20.0 Ω

25.0 Ω

27.0 Ω

30.0 Ω

33.0 Ω

40.0 Ω

47.0 Ω

50.0 Ω

56.0 Ω

75.0 Ω

100 Ω

Ordering Information:

MP915 - 50.0 - 1%

Model Number:

Resistor Value:

Tolerance

10.0 K

15.0 K

20.0 K

25.0 K

30.0 K

33.0 K

40.0 K

47.0 K

50.0 K

56.0 K

68.0 K

75.0 K

82.0 K

100 K

0.010 Ω 5%

0.015 Ω 5%

MP916 Standard Resistance Values:

Tolerance MP916 ±5% Standard (20% is available).

Packaging: MP915, MP916, MP925, MP930

resistors are packaged in plastic shipping tubes,

50 pieces per tube. These resistors are available

in a 50 piece minimum quantity and in full tube

quantity increments (i.e. 50, 100, 150, etc.). The

MP9100 resistors are packaged in plastic shipping

tubes, 25 pieces per tube.NewPower Resistor with Exposed Ceramic Heat DissipatingMounting Surface.

100 175

0

20

40

100

POWER RATING, %

80

60

150

A

B

25

A - MP915, MP916, MP925, MP930 Max. Temperature, TMax = 150°C

B - MP9100 Max. Temperature, TMax = 175°C

CASE TEMPERATURE, °C

DIMENSIONS IN INCHES AND (MILLIMETERS)

Figure 3

TO-247 Style

MP9100

All power and associated overload ratings are derated

based upon case temperature using the derating curve.

The case temperature is measured at the center of the

ceramic mounting surface, with the part properly

mounted and under electrical load. Without a heat sink,

when in free air at +25°C, the MP915 is rated for 1.25

watts, the MP916, MP925, MP930 are rated for 2.25

watts, and the MP9100 is rated for 3.5 watts.

The thermal design should satisfy the following equation:

Case Temperature (T

c

) + [Thermal Resistance (RθJC) x power applied (Watts)] ≤ TMAX

considering the full

operating temperature range of the application.

Mounting Note: Mount on a smooth, clean, and flat heat sink surface with a thermal interface material, such

as thermal grease. The entire exposed ceramic portion must be in thermal contact with the heat sink. When

screw mounting, use a compression washer which provides a mounting force of 150 to 300 pounds (665 to

1330 N). This will provide sufficient pressure on the package over time and through large temperature variations to maintain the maximum power dissipation capability. Mounting torque to avoid package damage is 8

in-lbs. (0.90 N-m). If a spring clip is used, a clip force of 8 to 30 pounds (35 to 130 N) is recommended to be

applied to the center of the package. The clip should be round or smooth in the contact area to avoid concentrating the load on a small point of the plastic body of the package. Another mounting option is to use a

pressure bar method which can achieve a greater mounting force with a greater contact area.

For additional applications information regarding mounting and pulse handling see the Caddock

Applications Notes at caddock.com or contact Applications Engineering.

Derating Curve Specifications:

Temperature Coefficient for MP915, MP916,

MP925, and MP930:

TC referenced to +25°C, ΔR taken at +150°C

0.50 ohms and above, -20 to +80 ppm/°C

0.050 ohm to 0.49 ohms, 0 to +200 ppm/°C

0.020 ohm to 0.049 ohm, 0 to +300 ppm/°C

0.010 ohm to 0.019 ohm, 0 to +500 ppm/°C

Temperature Coefficient for MP9100:

TC referenced to +25°C, ΔR taken at +175°C

0.50 ohms and above, -20 to +80 ppm/°C

0.050 ohm to 0.49 ohms, 0 to +150 ppm/°C

Operating Temperature: -55°C to TMAX

Inductance: MP915, MP916, MP925, and MP930

10nH typical; MP9100, 20nH typical, in series when

measured at a point 0.2 inches from the resistor

body.

DWV: The dielectric strength rating of 1500 VrmsAC

is based upon connections made between

terminals shorted, and the metal surface the part is

mounted to or a metal clip in contact with the top

surface of the part.

Insulation Resistance: 10,000 Megohms min.

The resistor element is electrically isolated from

the mounting surface.

Load Stability: 2,000 hours at rated power.

ΔR ±(1.0 percent + 0.0005 ohm) max. Power

rating dependent upon case temperature. See

derating curve.

Momentary Overload: 1.5 times rated power with

applied voltage not to exceed 1.5 times maximum

continuous operating voltage for 5 seconds. ΔR

±(0.5 percent + 0.0005 ohm) max.

Moisture Resistance: Mil-Std-202, Method 106.

ΔR ±(0.5 percent + 0.0005 ohm) max.

Thermal Shock: Mil-Std-202, Method 107, Cond. F.

ΔR ±(0.5 percent + 0.0005 ohm) max.

Shock: 100G, Mil-Std-202, Method 213, Cond. I.

ΔR ±(0.4 percent + 0.0005 ohm) max.

Vibration, High Frequency: Mil-Std-202, Method

204, Cond. D. ΔR ±(0.4 percent + 0.0005 ohm)

max.

Terminal Strength: Mil-Std-202, Method 211,

Cond. A (Pull Test) 5 lbs. ΔR ±(0.2 percent

+ 0.0005 ohm) max.

Terminal Material: Solderable

Measurement Note: For these specifications,

resistance measurement shall be made at a point

0.2 inch (5.08 mm) from the resistor body.

+

.030 ±.004

(.76 ± .10)

.025 ± .004 (.64 ±.10)

.200 ±.010

(5.08 ±.26)

.450 ±.050

(11.43 ±1.27)

.115 ±.010

(2.92 ±.26)

MP915

0.10Ω

1%

.110 ±.010

(2.79 ±.26)

.053 ± .007

(1.35 ± .18)

.058 ±.007 (1.47 ±.18)

.320 ±.010

(8.12 ±.26)

.094 ±.004

(2.39 ±.10) DIA.

CL

.440 ±.010

(11.18 ±.26)

.080 ±.020

(2.03 ±.51)

.640 ±.010

(16.26 ±.26)

.030 ±.004

(.76 ± .10)

.200 ±.010 .025 ± .004 (.64 ±.10)

(5.08 ±.26)

.500 ±.050

(12.70 ±1.27)

.130 ±.030

(3.30 ±.76)

.125 ±.010

(3.18 ±.26)

.410 ±.010

(10.41 ±.26)

MP930

10.0

1%

.125 ±.010

(3.18 ±.26)

.125 ±.004

(3.18 ±.10) DIA.

CL

.053 ± .007

(1.35 ± .18)

.070 ±.010 (1.78 ±.26)

MP916

MP915

Model

No. Comments

MP930

MP925

TO-220 Style

TO-220 Style

Package

TO-220 Style

TO-126 Style

0.010 Ω 0.019 Ω

0.020 Ω 1.00 K

Min. Max.

Resistance

0.020 Ω 4.99 K

5.00 K 100 K

16 Watts*

15 Watts*

Power

Rating

30 Watts*

25 Watts*

Max.

Voltage

Power

Limited

200

250

500

Thermal Resistance

RθJC

Film (J) to Case (C)

8.33°C/Watt

5.00°C/Watt

4.17°C/Watt

7.81°C/Watt

150°C

Figure 2

Figure 1

Dimensions

Figure 2

Figure 2

Max. Temp.

T MAX

150°C

150°C

150°C

MP9100 TO-247 Style 0.050 Ω 100 Ω 100 Watts* 1.50°C/Watt 175°C Figure 3

Power

Limited

Ceramic mounting surface

Ceramic mounting surface

Ceramic mounting surface

Ceramic mounting surface

Ceramic mounting surface

Figure 1

TO-126 Style

MP915

Figure 2

TO-220 Style

MP916, MP925

and MP930

0.143 ± 0.004

(3.63 ± 0.10) Dia.

0.620 ± 0.010

(15.75 ± 0.26)

0.110 ± 0.030

(2.79 ± 0.76)

0.570 ± 0.050

(14.48 ± 1.27)

0.195 ± 0.010

(4.95 ± 0.26)

0.095 ± 0.010

(2.41 ± 0.26)

0.143 ± 0.007

(3.63 ± 0.18)

0.060 ± 0.004

(1.52 ± 0.10)

0.400 ± 0.010

(10.16 ± 0.26)

0.210 ± 0.010

(5.33 ± 0.26)

0.815 ± 0.010

(20.70 ± 0.26)

C

L

MP 9100

50.0

1%

0.032 +0.004 / -0.010

(0.81 +0.10 / -0.26)

* Derating Using Case Temperature (TC):

Page 2 of 2

28_IL102.1004

15 Watts at +25°C Case Temperature, derated to zero at +150°C.

Exposed Ceramic Heat Dissipating Mounting Surface.

Resistance Range of 0.020 ohm to 1 K.

Non-Inductive Design.

Use your thermal design experience with power semiconductors in TO-126, TO-220,

and TO-247 style power packages to help you get the most out of this unique family of

power resistors. The thermal design issues are the same where power handling

capability is based on the case temperature which is maintained in your design.

MP915 TO-126 Style Power Package

Up to 30 Watts at +25°C Case Temperature, derated to zero at +150°C.

Exposed Ceramic Heat Dissipating Mounting Surface.

Resistance Range of 0.010 ohm to 100 K.

Non-Inductive Design.

MP916, MP925, and MP930 TO-220 Style Power Package

100 Watts at +25°C Case Temperature, derated to zero at +175°C.

Exposed Ceramic Heat Dissipating Mounting Surface.

Resistance Range of 0.050 ohm to 100 ohm.

Non-Inductive Design.

MP9100 TO-247 Style Power Package

Low Cost Heat Sink Mountable Design featuring

an Exposed Ceramic Heat Dissipating Mounting Surface

The MP900 and MP9000 Series Kool-Pak®

Power

Film Resistors are constructed with Caddock's

Micronox®

resistance film fired onto a flat ceramic

substrate. The terminal attachment and resistance

element geometry are configured to provide

outstanding non-inductive performance. The

ceramic substrate is positioned in the molded

package such that the resistor element and terminal

attachment areas on the substrate are

encapsulated in the molded body with the other side

of the ceramic being exposed flush with the back

mounting surface of the device. This construction is

covered by one or more issued patents, also

patents pending.

For custom resistance values and tolerances contact

applications engineering.

Construction of MP900 and

MP9000 Series:

0.020 Ω 5%

0.025 Ω 5%

0.030 Ω 5%

0.033 Ω 5%

0.040 Ω 5%

0.050 Ω

0.075 Ω

0.10 Ω

0.15 Ω

0.20 Ω

0.25 Ω

0.30 Ω

0.33 Ω

0.40 Ω

0.50 Ω

0.75 Ω

1.00 Ω

1.50 Ω

2.00 Ω

2.50 Ω

3.00 Ω

3.30 Ω

4.00 Ω

5.00 Ω

7.50 Ω

8.00 Ω

10.0 Ω

12.0 Ω

15.0 Ω

20.0 Ω

25.0 Ω

27.0 Ω

30.0 Ω

33.0 Ω

40.0 Ω

47.0 Ω

50.0 Ω

56.0 Ω

75.0 Ω

100 Ω

120 Ω

150 Ω

200 Ω

250 Ω

300 Ω

330 Ω

400 Ω

470 Ω

500 Ω

560 Ω

750 Ω

1.00 K

1.50 K

2.00 K

2.50 K

3.00 K

3.30 K

4.00 K

5.00 K

7.50 K

MP915, MP925, and MP930

Standard Resistance Values:

Tolerance MP915, MP925, and MP930 ±1% Standard - except

as noted. (5% and 20% are available for most resistance values).

0.050 Ω

0.075 Ω

0.10 Ω

0.15 Ω

0.20 Ω

0.25 Ω

0.30 Ω

0.33 Ω

0.40 Ω

0.50 Ω

0.75 Ω

1.00 Ω

1.50 Ω

2.00 Ω

2.50 Ω

3.00 Ω

3.30 Ω

4.00 Ω

5.00 Ω

7.50 Ω

8.00 Ω

10.0 Ω

12.0 Ω

15.0 Ω

MP9100 Standard Resistance Values:

Tolerance MP9100 ±1% Standard.

20.0 Ω

25.0 Ω

27.0 Ω

30.0 Ω

33.0 Ω

40.0 Ω

47.0 Ω

50.0 Ω

56.0 Ω

75.0 Ω

100 Ω

Ordering Information:

MP915 - 50.0 - 1%

Model Number:

Resistor Value:

Tolerance

10.0 K

15.0 K

20.0 K

25.0 K

30.0 K

33.0 K

40.0 K

47.0 K

50.0 K

56.0 K

68.0 K

75.0 K

82.0 K

100 K

0.010 Ω 5%

0.015 Ω 5%

MP916 Standard Resistance Values:

Tolerance MP916 ±5% Standard (20% is available).

Packaging: MP915, MP916, MP925, MP930

resistors are packaged in plastic shipping tubes,

50 pieces per tube. These resistors are available

in a 50 piece minimum quantity and in full tube

quantity increments (i.e. 50, 100, 150, etc.). The

MP9100 resistors are packaged in plastic shipping

tubes, 25 pieces per tube.NewPower Resistor with Exposed Ceramic Heat DissipatingMounting Surface.

100 175

0

20

40

100

POWER RATING, %

80

60

150

A

B

25

A - MP915, MP916, MP925, MP930 Max. Temperature, TMax = 150°C

B - MP9100 Max. Temperature, TMax = 175°C

CASE TEMPERATURE, °C

DIMENSIONS IN INCHES AND (MILLIMETERS)

Figure 3

TO-247 Style

MP9100

All power and associated overload ratings are derated

based upon case temperature using the derating curve.

The case temperature is measured at the center of the

ceramic mounting surface, with the part properly

mounted and under electrical load. Without a heat sink,

when in free air at +25°C, the MP915 is rated for 1.25

watts, the MP916, MP925, MP930 are rated for 2.25

watts, and the MP9100 is rated for 3.5 watts.

The thermal design should satisfy the following equation:

Case Temperature (T

c

) + [Thermal Resistance (RθJC) x power applied (Watts)] ≤ TMAX

considering the full

operating temperature range of the application.

Mounting Note: Mount on a smooth, clean, and flat heat sink surface with a thermal interface material, such

as thermal grease. The entire exposed ceramic portion must be in thermal contact with the heat sink. When

screw mounting, use a compression washer which provides a mounting force of 150 to 300 pounds (665 to

1330 N). This will provide sufficient pressure on the package over time and through large temperature variations to maintain the maximum power dissipation capability. Mounting torque to avoid package damage is 8

in-lbs. (0.90 N-m). If a spring clip is used, a clip force of 8 to 30 pounds (35 to 130 N) is recommended to be

applied to the center of the package. The clip should be round or smooth in the contact area to avoid concentrating the load on a small point of the plastic body of the package. Another mounting option is to use a

pressure bar method which can achieve a greater mounting force with a greater contact area.

For additional applications information regarding mounting and pulse handling see the Caddock

Applications Notes at caddock.com or contact Applications Engineering.

Derating Curve Specifications:

Temperature Coefficient for MP915, MP916,

MP925, and MP930:

TC referenced to +25°C, ΔR taken at +150°C

0.50 ohms and above, -20 to +80 ppm/°C

0.050 ohm to 0.49 ohms, 0 to +200 ppm/°C

0.020 ohm to 0.049 ohm, 0 to +300 ppm/°C

0.010 ohm to 0.019 ohm, 0 to +500 ppm/°C

Temperature Coefficient for MP9100:

TC referenced to +25°C, ΔR taken at +175°C

0.50 ohms and above, -20 to +80 ppm/°C

0.050 ohm to 0.49 ohms, 0 to +150 ppm/°C

Operating Temperature: -55°C to TMAX

Inductance: MP915, MP916, MP925, and MP930

10nH typical; MP9100, 20nH typical, in series when

measured at a point 0.2 inches from the resistor

body.

DWV: The dielectric strength rating of 1500 VrmsAC

is based upon connections made between

terminals shorted, and the metal surface the part is

mounted to or a metal clip in contact with the top

surface of the part.

Insulation Resistance: 10,000 Megohms min.

The resistor element is electrically isolated from

the mounting surface.

Load Stability: 2,000 hours at rated power.

ΔR ±(1.0 percent + 0.0005 ohm) max. Power

rating dependent upon case temperature. See

derating curve.

Momentary Overload: 1.5 times rated power with

applied voltage not to exceed 1.5 times maximum

continuous operating voltage for 5 seconds. ΔR

±(0.5 percent + 0.0005 ohm) max.

Moisture Resistance: Mil-Std-202, Method 106.

ΔR ±(0.5 percent + 0.0005 ohm) max.

Thermal Shock: Mil-Std-202, Method 107, Cond. F.

ΔR ±(0.5 percent + 0.0005 ohm) max.

Shock: 100G, Mil-Std-202, Method 213, Cond. I.

ΔR ±(0.4 percent + 0.0005 ohm) max.

Vibration, High Frequency: Mil-Std-202, Method

204, Cond. D. ΔR ±(0.4 percent + 0.0005 ohm)

max.

Terminal Strength: Mil-Std-202, Method 211,

Cond. A (Pull Test) 5 lbs. ΔR ±(0.2 percent

+ 0.0005 ohm) max.

Terminal Material: Solderable

Measurement Note: For these specifications,

resistance measurement shall be made at a point

0.2 inch (5.08 mm) from the resistor body.

+

.030 ±.004

(.76 ± .10)

.025 ± .004 (.64 ±.10)

.200 ±.010

(5.08 ±.26)

.450 ±.050

(11.43 ±1.27)

.115 ±.010

(2.92 ±.26)

MP915

0.10Ω

1%

.110 ±.010

(2.79 ±.26)

.053 ± .007

(1.35 ± .18)

.058 ±.007 (1.47 ±.18)

.320 ±.010

(8.12 ±.26)

.094 ±.004

(2.39 ±.10) DIA.

CL

.440 ±.010

(11.18 ±.26)

.080 ±.020

(2.03 ±.51)

.640 ±.010

(16.26 ±.26)

.030 ±.004

(.76 ± .10)

.200 ±.010 .025 ± .004 (.64 ±.10)

(5.08 ±.26)

.500 ±.050

(12.70 ±1.27)

.130 ±.030

(3.30 ±.76)

.125 ±.010

(3.18 ±.26)

.410 ±.010

(10.41 ±.26)

MP930

10.0

1%

.125 ±.010

(3.18 ±.26)

.125 ±.004

(3.18 ±.10) DIA.

CL

.053 ± .007

(1.35 ± .18)

.070 ±.010 (1.78 ±.26)

MP916

MP915

Model

No. Comments

MP930

MP925

TO-220 Style

TO-220 Style

Package

TO-220 Style

TO-126 Style

0.010 Ω 0.019 Ω

0.020 Ω 1.00 K

Min. Max.

Resistance

0.020 Ω 4.99 K

5.00 K 100 K

16 Watts*

15 Watts*

Power

Rating

30 Watts*

25 Watts*

Max.

Voltage

Power

Limited

200

250

500

Thermal Resistance

RθJC

Film (J) to Case (C)

8.33°C/Watt

5.00°C/Watt

4.17°C/Watt

7.81°C/Watt

150°C

Figure 2

Figure 1

Dimensions

Figure 2

Figure 2

Max. Temp.

T MAX

150°C

150°C

150°C

MP9100 TO-247 Style 0.050 Ω 100 Ω 100 Watts* 1.50°C/Watt 175°C Figure 3

Power

Limited

Ceramic mounting surface

Ceramic mounting surface

Ceramic mounting surface

Ceramic mounting surface

Ceramic mounting surface

Figure 1

TO-126 Style

MP915

Figure 2

TO-220 Style

MP916, MP925

and MP930

0.143 ± 0.004

(3.63 ± 0.10) Dia.

0.620 ± 0.010

(15.75 ± 0.26)

0.110 ± 0.030

(2.79 ± 0.76)

0.570 ± 0.050

(14.48 ± 1.27)

0.195 ± 0.010

(4.95 ± 0.26)

0.095 ± 0.010

(2.41 ± 0.26)

0.143 ± 0.007

(3.63 ± 0.18)

0.060 ± 0.004

(1.52 ± 0.10)

0.400 ± 0.010

(10.16 ± 0.26)

0.210 ± 0.010

(5.33 ± 0.26)

0.815 ± 0.010

(20.70 ± 0.26)

C

L

MP 9100

50.0

1%

0.032 +0.004 / -0.010

(0.81 +0.10 / -0.26)

* Derating Using Case Temperature (TC):

Page 2 of 2

28_IL102.1004